Disclosure: This article is sponsored content from Designs for Vision as part of our sponsored partner program. For a free, no-obligation 60-day trial of Designs for Vision loupes, click here.

I took a train from Grand Central Station to Bohemia, New York, while attending the Greater New York Dental Meeting this past year. It was a short and welcome interruption from the relentless pace of Times Square to explore something quieter and more meaningful: the story of how innovation in loupe manufacturing truly begins. I came to learn about optics. I left thinking about leadership. Here’s an introduction to the people and departments that power this industry-leading operation.

Waiting for me at the Designs for Vision headquarters was Dr. Richard Feinbloom, the company’s current president and the son of its founder. Richard would become my guide for the day, but more than that, the voice of the company’s past, present, and future. With his unmistakable green glasses and deep institutional knowledge, Richard was not simply walking me through a facility; he was welcoming me into a legacy.

The Foundation of Precision

When we speak of innovation in the dental profession, we often focus on the instruments we rely on daily, such as scalers that access tight subgingival contours, mirrors that reflect the finest anatomical details, and composite instruments that sculpt restorations to exact anatomy. We consider the materials that evolve with science and the rising standards of care that push our skills further. But behind every precise margin and successful case lies a deeper foundation: the craftsmanship and engineering that make such precision possible. Without a clear, uncompromised vision, even the most advanced tools fall short. The brands we trust were not built in haste; they were shaped over decades by those who understand that our hands are only as accurate as what our eyes can see.

One such legacy belongs to Designs for Vision, a company whose reputation precedes it in the halls of academia, the operatories of private practice, and the surgical suites of medical institutions. Headquartered in Bohemia, New York, Designs for Vision has spent over 70 years designing and handcrafting magnification systems that enable clinicians to see the invisible, treat the untreatable, and deliver care with greater confidence.

For a free, no-obligation 60-day trial of Designs for Vision loupes, click here.

From Vision to Reality: The Manufacturing Process

Founded in 1958 by Dr. William Feinbloom, a low vision optometrist and inventor, the company initially focused on developing devices to assist people with visual impairments. What began as a social mission to restore visual function evolved into a medical and dental optics company with a singular goal: to give healthcare professionals the clearest possible view of their working environment. In doing so, they helped define an entire category of clinical equipment that few had imagined and even fewer could perfect.

Today, that mission continues through a team of dedicated engineers, lens designers, machinists, and optical technicians who bring the Feinbloom vision into the future. Their headquarters is more than a factory. It is a design laboratory, a manufacturing hub, and a place where generational knowledge is passed down through mentorship and mastery.

When I arrived, I expected a high-tech operation. What I found exceeded those expectations. The machines were impressive, but it was the people who transformed the space into something remarkable. There was an energy that felt focused and thoughtful. The smell of metal polish in the air, the soft rhythm of lens surfacing, and the deliberate arrangement of tools on workbenches each told a story of care and continuity. Work stations displayed mechanical drawings on one side and family photos on the other.

I have worn these loupes in thousands of procedures, trusted them to guide my hands and shape my judgment. But I had never once stopped to consider where they came from. As I walked through the hallways, met the team, and listened to their stories, it became clear: this company is powered by people who take immense pride in something most of us never get to see, the inside of the loupe.

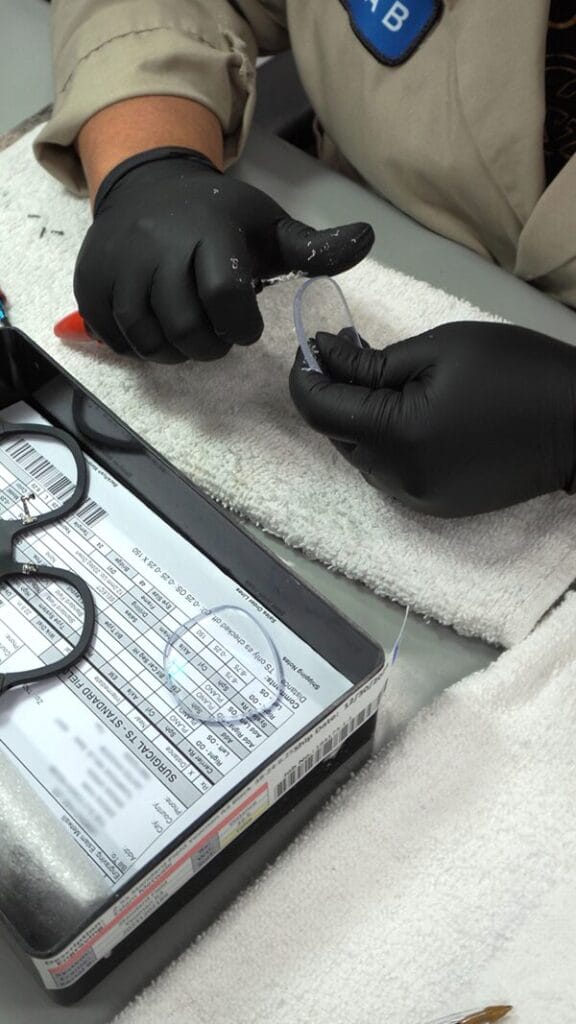

The tour began at the core of optical manufacturing, where raw materials are transformed into the customized systems clinicians rely on every day. In the Molding and Surfacing Departments, base lenses are shaped, ground, and polished to exact specifications. This is where technical skill meets consistency. Each curve, each coating, and each alignment is engineered with the understanding that the final product must accommodate not only the clinician’s face but also the unique needs of their working distance, posture, and procedure type.

Courtesy of Irene Iancu/Toothlife Media Inc.

We moved into the Coating Room, a sterile environment where lenses receive anti-reflective treatments and protective layers. Each application enhances durability and sharpens clarity, improving contrast and comfort during long procedures under operatory lighting.

The Assembly Department revealed the precision and personalization behind every frame. Highly trained technicians fit lenses into their frames, adjusting telescope positions and securing each component by hand. This is not assembled by automation. It is a practice of refinement. Measurements are taken, verified, and revised until the finished loupe meets both a prescription and a clinician’s rhythm.

At every station, there was a shared awareness. The tools developed here are designed for complex procedures and high-stakes decisions, ranging from oral surgery to endodontic therapy to full-mouth rehabilitations. There is no acceptable margin for error. That level of responsibility is evident in the way each technician approaches their work.

For a free, no-obligation 60-day trial of Designs for Vision loupes, click here.

A Legacy of Leadership and Culture

As Richard walked me through the departments, he told stories about nearly every room, explaining how one area used to be the packaging center and how another was once part of an experimental optics lab. His connection to the space ran deeper than strategy or leadership. He had held many of these jobs himself. From lens polishing to logistics, Richard’s presence in the company is not symbolic; it is practical. He leads by working, by understanding, and by remembering.

In his words, “We have always believed that when a clinician sees better, they do better. So, our job is to make sure they see everything.”

That guiding principle is visible in every inch of the building. Innovation here is not limited to product design or material science. It lives in the culture, in the way people speak about their roles, and in the careful calibration of every tool, even those that will never carry a name tag or stand on a podium.

The Museum of Memory

There was one hallway, in particular, that I will never forget.

It was a long, quiet corridor lined with framed photographs, handwritten letters, and preserved artifacts, a museum of memory within a working factory. Black-and-white portraits of longtime employees hung beside candid color photos of those same individuals decades later, still smiling, still working. Family photos were pinned up next to drawings from children, thanking their parents, and mixed in were pictures of pets, plants, picnics, and paintings.

Courtesy of Irene Iancu/Toothlife Media Inc.

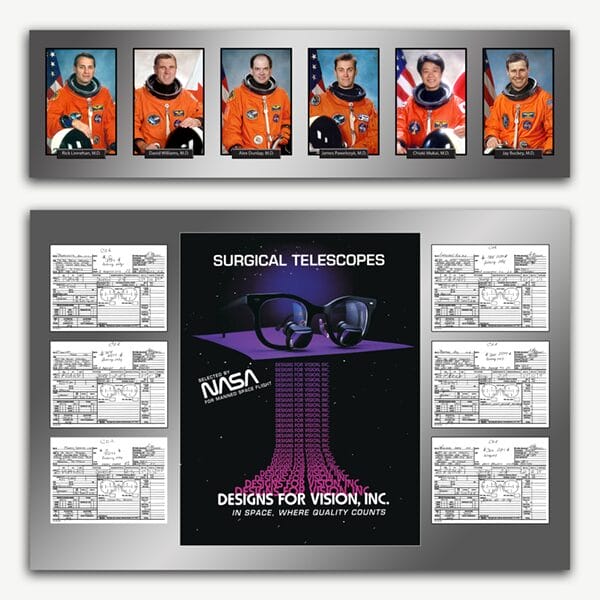

There were plaques for service milestones, letters from customers, signed photos from celebrities, and newspaper clippings of past presidents wearing their frames. Published articles from The New York Times, the cover of Life magazine depicting a surgeon in full PPE wearing telescopes, and a glass case displaying the original prescription for the NASA doctors who were fitted for Designs for Vision loupes that were used during a shuttle mission to conduct experiments in zero gravity.

Courtesy of Designs for Vision

For a free, no-obligation 60-day trial of Designs for Vision loupes, click here.

Another section highlighted the company’s philanthropic ventures, including missions to underserved communities with snapshots of clinicians delivering care where care had never been offered before. It was a testament not only to what the company makes, but to who they are.

Standing in that hallway felt like stepping into someone’s home. Not a showroom, but a lived-in, loved-in space. A place where people build careers, raise families, and leave their mark. That kind of continuity is rare. That kind of loyalty must be earned.

Perhaps that is the true story of Designs for Vision. A company founded on optics and sustained through relationships. Relationships between makers and users, mentors and apprentices, past and present. What is built here does not simply serve the moment. It is built to endure.

These stories cannot be found in a product catalogue. They are embedded in the walls, in the processes, and in the pride of every person who shapes this work. As a clinician, it reminded me that the tools we use are only as extraordinary as the people who make them. In dentistry, precision is personal. And when your work depends on what you see, it matters to know that someone has already seen it through.

For a free, no-obligation 60-day trial of Designs for Vision loupes, click here.

Watch Irene’s first video in her series of visiting Designs for Vision’s factory.

View this post on Instagram

For a free, no-obligation 60-day trial of Designs for Vision loupes, click here.